Woodworkers of Central New York

- Home

- Special Interest Groups

- Resources

-

Gallery

-

Special Events

- Maker Faire

- Summer Soiree / Education Day

- Woodworker's Challenge >

- Wood Burning Training

- Virtual Contests >

- Library Displays

- Members in the News

- Lumber Cutting

- Shaker Box Class

- Demo - Rebecca DeGroot

- Guest Turner - Emiliano Achaval

- National Turner - Paul Petrie

- National Carver - Arland Zeittler

- National Turner - Dennis Fuge

- CANCELLED - National Carver - Jim O'Dea

- CANCELLED - The Woodworking Show 2020

-

Community Support

With the COVID-19 virus cancelling all events in April, members were encouraged to work on projects and send photos of those projects for display here and on the Facebook page.

Irreverent Greenman (or Jack-in-the-Green)

Carved for the NWA Show in 2019, the Greenman was traditionally an element of religion before Christianity. They were carved into church misericords, demonized, and often shown in pain with greenery growing out of their noses and mouths. Mike Bloomquist carved this from butternut with an attitude, which explains the title. The dimensions are 13" wide x 23" tall x 3" thick. It is finished with satin polyurethane.

Carved for the NWA Show in 2019, the Greenman was traditionally an element of religion before Christianity. They were carved into church misericords, demonized, and often shown in pain with greenery growing out of their noses and mouths. Mike Bloomquist carved this from butternut with an attitude, which explains the title. The dimensions are 13" wide x 23" tall x 3" thick. It is finished with satin polyurethane.

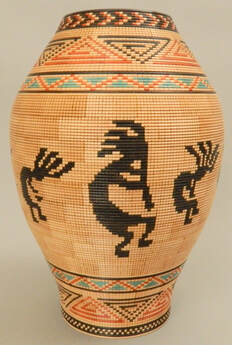

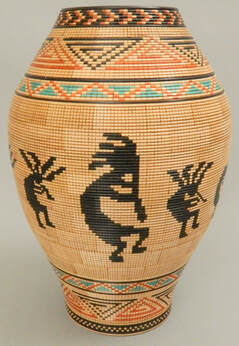

Jim & Shelly Kent collaborate on spectacular projects on a regular basis. Jim turns the vessels, showing Shelly what he's doing along the way. She then decides how she is going to embellish them. The technique they use is called basket weave illusion. Once we return to in-person sessions, we will have Jim and Shelly gives us a talk about their work. Until then, enjoy these stunning projects they've shared with us.

Indian vase with turquoise inlay - both front and back.

Segmented bowl with graphic design.

Jim often creates less "involved" projects. Recently, he completed these three - a walnut pentagon box, a box elder pentagon box, and a spalted maple bowl.

Ray Smith isn't able to turn much during the winter months as his shop is in his cold garage shop. However, with the warm weather he was able to spend time on the lathe. The "in progress" photo shows the new "S" curve tool rest purchased with a Craft Supplies gift card. The resulting bowl is shown in the second two photos. Ray did not notice the knot hole in the blank - from the center of the tree - before he started turning. Of course, the resulting bowl can't hold water as it has a hole in the bottom! However, it could be used as a funnel! Ray notes that it sure is great to be able to turn again!

Kyle Matzke acquired some "Fordite" and turned it into this pen. Fordite (aka Detroit Agate) is actually old enamel paint slag that hardened and was then scraped off and considered trash. How was it created? Starting in the 1920s, auto manufacturers began painting car bodies using a hand-spraying technique to speed up the painting process. Overspray would accumulate in the paint bays. Over time, layer upon colorful layer built up. The pieces of enamel paint slag were repeatedly hardened in the ovens in which the cars went to cure the paint, with some of the layers baked up to 100 times. Eventually, the paint clumps got in the way of vehicle assembly and had to be removed. It takes about 997 layers of paint to build a 1-inch thick fordite slag specimen. Groups of factory workers eventually started salvaging the material and it is considered a "gem".

Note that the blanks are not cheap. One pen blank at Woodturningz is about $40.

Note that the blanks are not cheap. One pen blank at Woodturningz is about $40.

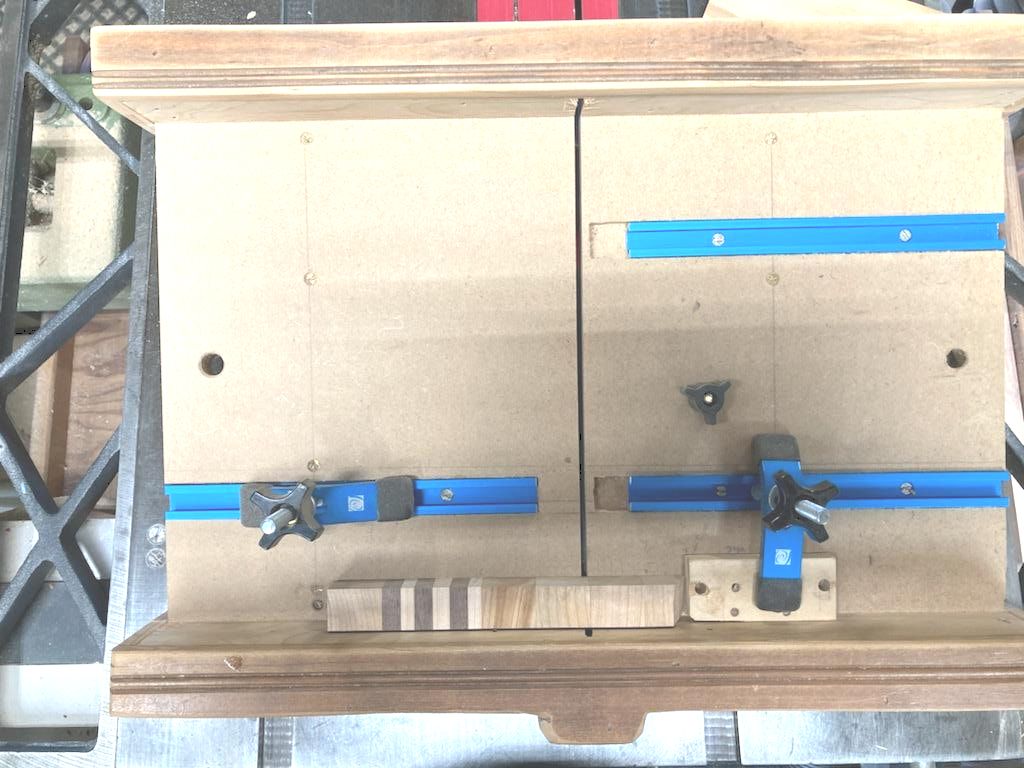

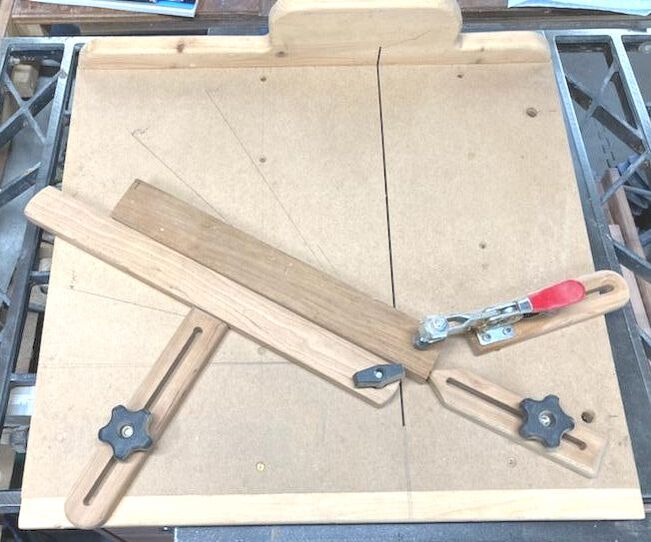

The March 3, 2021 meeting focused on jigs for any genre of woodworking. Terry Vermilyea missed that event but sent in his jigs after the fact. He shows two different jigs - one for cutting accurate pen blanks and one for cutting segment for segmented bowls.

This pen blank jig is used heavily by Terry as he usually prepares 200 blanks a week for The Woodworking Shows. He said that repetitive square cuts and blank cutoffs are accurately completed with this jig. He added that if careful, the blanks can be cut so accurately that you don't have to square the ends as they match the length of the brass inserts. The first photo shows the jig in use to create square cuts. The second photo shows that with an insert, you can make pens at angles when they are turned such that they look like barber poles after final glue-up and turning.

The second jig Terry uses to cut pieces to ultimately create segmented turnings.

Jim Yonkers has a shop near his son's in Georgia. For tools, Jim has some serious antiques! His "new" drill press is a 1923 Meyersford 13" dual table unit. The quill is retracted by weight in the column connected by a chain. The upper table swings away to allow use of the lower table which is fully height adjustable on ways. The quill is MT1. The table has attachments such as V bloc and domed & hollow point fixtures for precision drilling. Originally, the drill was belt driven although it is currently outfitted with a small motor until Jim & his son fabricate the required belt driven components for a shop all line drive. The drill press was originally sold by CH Wood Company of Syracuse. Jim is looking for more info on this company.

Jim also sent along photos of his 1903 Crescent band saw. He added a Kreg saw fence and some guard sections. This saw is temporarily operated by a DC motor until the drive line is installed. The lathe? It's is an 1850 rebuilt to increase to 10" with a head stock spacer. It was made in Bridgeport, CT by a Heald predecessor. It is currently attached to the drive line and run with a 5HP DC motor and controller.

Jim also sent along photos of his 1903 Crescent band saw. He added a Kreg saw fence and some guard sections. This saw is temporarily operated by a DC motor until the drive line is installed. The lathe? It's is an 1850 rebuilt to increase to 10" with a head stock spacer. It was made in Bridgeport, CT by a Heald predecessor. It is currently attached to the drive line and run with a 5HP DC motor and controller.

Mark's parents decided to change up the fireplaces in the family home. They switched from wood-burning to gas-fired and added beautiful stone to the face. Mark used a slab of ash cut during one of the club lumber cutting events to create two beautiful mantles to complete the renovation.

Proudly powered by Weebly

- Home

- Special Interest Groups

- Resources

-

Gallery

-

Special Events

- Maker Faire

- Summer Soiree / Education Day

- Woodworker's Challenge >

- Wood Burning Training

- Virtual Contests >

- Library Displays

- Members in the News

- Lumber Cutting

- Shaker Box Class

- Demo - Rebecca DeGroot

- Guest Turner - Emiliano Achaval

- National Turner - Paul Petrie

- National Carver - Arland Zeittler

- National Turner - Dennis Fuge

- CANCELLED - National Carver - Jim O'Dea

- CANCELLED - The Woodworking Show 2020

-

Community Support